20X6000mm CNC Cutting Machine Shearing Machine Shear Machine Guillotine Shear with Dac360

FAQ Q1:How Can I calculate the Machine Capacity? A: Just send me the Max thickness and Length .Engineer will tell us the

Description

Basic Info

| Automation | Automatic |

| Certification | CE, ISO 9001:2000, ISO 9001:2008, EPA, Nr12 |

| Condition | New |

| Warranty | 3 Years |

| Transport Package | Container Loading |

| Specification | 6mm-60mm |

| Trademark | BAMBEOCNC |

| Origin | China |

| HS Code | 84623990 |

| Production Capacity | 20sets/Per Month |

Product Description

| Hydraulic Guillotine shear Features |

| 1.The machine adopts full steel weking structure,heating to eliminate stress,with high strength and good rigidity. 2. The German large floor boring and milling machine is used to make recision machining with one time processing method to ensure the machining precision. 3.Advanced integrated hydraulic system with and excellent reliabitity quality. 4.Rapidly,accurately and conveniently adjusting the blade clearance by motor 5.The adjustable rake angle can minimize plate deformation. 6.As the cutting beam has been designed in inner-inclined structure,it is easy for plates to fall down and the accuracy of products can be also guaranteed. 7.Shearing in sections,shadow-line cutting. 8.Counter for the motorized back gauge. 9.Back support device (optional). Hydraulic Guillotine Shearing Machine, Steel Plate Cutting Machine Cutting length from 2000mm to 13000mm Cutting thickness from 6mm to 60mm Hydraulic Guillotine Shearing Machine, Steel Plate Cutting Machine Precision Hydraulic Guillotine Shearing Machine |

| Controller | Estun E21s |

| ----HD LCD display, with both Chinese and English language options, a display programming parameters, faster and more convenient programming ----Backgauge control:Smart positioning, can also be manually adjusted as needed to remove the mechanical hand positioning device. ----Cut Stroke: Built-shearing time relay, simple operation, cost savings --Shear angle: Built shear angle adjustment function, eliminating the angle indicators and buttons ----Blade gap: encoder feedback, time display blade gap size, simple operation ----Having a key parameter backup and restore functionality, you can always restore the parameters as required, reducing maintenance costs ----All keys on the panel are micro-switches, through EMC, high temperature, vibration and other rigorous testing to ensure product stability and service life. ----CE certified to meet the needs of overseas markets. | |

| Standard Configuration | ||

| 1. | Controller | Estun E21 Controller |

| 2. | Hydraulic System | Bosch Rexroth From Germany |

| Hydraulic system: --Adopt integrated hydraulic control system, more reliable and easy for maintenance.Hydraulic system is from Bosch - Rexroth,Germany. --All seals in cylinder is PARKER from USA,the most famous brand,good quality and high performance --Overload overflow protection is outfitted to hydraulic system,which can assure no leakage,and the oil level can be read or seen directly. --The hydraulic system is made in compliance with current regulations (Directive 98/37 EC). | ||

| 3. | Main Motor | Siemens From Germany |

| 4. | Main Electrics | SCHNEIDER from France |

| Electrical system and the safety interlock: --Electrical Cabinet under the standard of IP65, Electrical under international CE Standard, safe and reliable, strong anti interference capability --Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch,easy to operate --Front Side Covers with safety switches, Back light safety guards (Category-4),Foot pedal conforming to CE regulation. | ||

| 5. | Seal Ring | NOK From Japan |

| 6. | Pipe Connector | EMB From Germany |

| 7. | Ball Srew | Hiwin From Taiwan |

| 8. | Limit Switch | SCHNEIDER from France |

| 9. | Pump | Sunny From USA |

| 10. | Foot Switch | Karcon From South Korea |

| No | Items | parameters | remarks |

| 1 | Upper Down blade | 2 | set |

| 3 | Bolt &Nut | 8 | |

| 4 | feet nut washer | 4 | |

| 5 | Allen wrench&Grease Gun | 1 set | 3 to 14 mm (maintenance tool) |

| 6 | technical documents | certificate of the product, including operation and maintenance manual, electrical, hydraulic schematics, purchased parts inventory, basic maps, packing list. | |

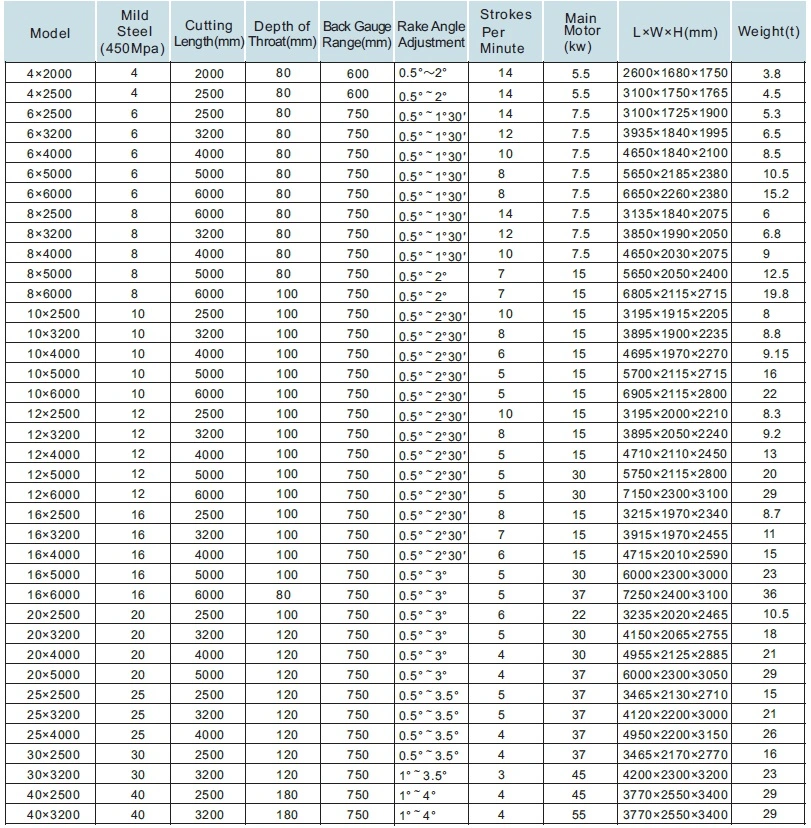

| Technical Parametres |

FAQ

Q1:How Can I calculate the Machine Capacity?

A: Just send me the Max thickness and Length .Engineer will tell us the capacity directly

Q2:How about the machine warranty?Is the whole machine?

A:We canoffer 4 years warranty for the following parts :

--Hydraulic System with pump and Valve

--Hydraulic Cylinders

--Electric units

--Hydraulic Cylinders

--Gasket Ring( We will send you extra with the machine also )

--Tube Connector

--Control Button

--Limit Switch

--Controller

During the warranty period we provide any accessories for free

Q3: What is your MOQ?

A:To let more customer know our quality, we accepty trial order service,So the MOQ is 1 set.

Q4: what is your delivery time?

A:We supply prompt delivery time:30-35days.

Q5:What kind of Service does your company support?

A:Engineers Available to Service Machinery Overseas

Prev: High-Efficiency Hydraulic Guillotine Shear Metal Scrap Gantry Steel Rebar Iron Shearing

Next: Scrap Metal Chip Compactor Briquette Machine Press Making Machine

Our Contact

Send now