China Leading All Kinds of Non-Ferrous Metals Recovery in Car Fluff Recycling

Description

Basic Info

| Model NO. | ECS |

| Processing Capacity | 1-20tph for Non-Magnetic Materials Separation |

| Dimension(L*W*H) | 3670X2000X1285mm |

| Motor | Nord or Simens High Quality Motor |

| Transport Package | as Export Packing Is Required |

| Specification | ISO |

| Trademark | JSYY |

| Origin | Fushun, Liaoning, China |

| HS Code | 85051190 |

| Production Capacity | 50sets/Month |

Product Description

|

|

|

|

Application of eddy current non-ferrous metal separator

1. Recovery Of Non-ferrous Metals From Waste Materials.

Separation of ferrous and non-ferrous metals in Shredded End-of-Life vehicle/cars (ELVs) & auto shredder residue(ASR)recycling industryFerrous and non-ferrous metals recovery from shredded End-of-Life domestic applicationAluminum recovery from shredded and pre-treated co-mingle recyclables metal (Zorba) recycling industryRecovery of non-ferrous metals from slag after the incineration of municipal waste.steel slag scraps recycling industrycrushed Bulky City waste recyclingnon-ferrous dross recovery from foundry sand in aluminum-shell-sand recycling lines.non-ferrous recovery in Waste Electrical and Electronic Equipment(WEEE) recycling plantsnon-ferrous scrap from crushed waste electrolytic capacitors

2. Separation Of Non-ferrous Metals From Recyclable Materials.

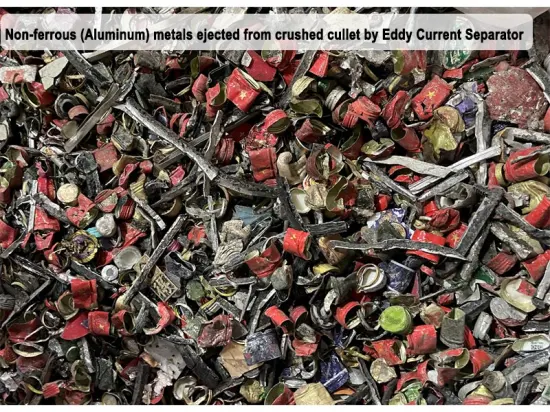

non-ferrous scraps separation from cullet in glass recycling aluminum scraps separation in UPVC window recycling.non-ferrous components (such as brass rivets and hinges) separation in the timber recycling industry.non-ferrous scraps separation in the plastic recycling industryNon-ferrous scraps are separated from crushed rubber.Aluminum cans sorted from municipal solid waste

FAQ

Q: What kind of metal is magnetic eddy current applied to?

A: suitable for crushed mixed metal scraps sorting industries

often the mixture is composed of steel, iron, etc ferromagnetic metal and aluminum, copper, and brass. etc non-ferrous scraps separation from materials of size >3mm.

Q: Which type should I use for my recycling plant?

A: In order to recommend the most suitable model, please let us know the material`s situation .including the composition, size, handling capacity and expected separation result.

Q: What are the pros and cons of a concentric pole rotor compared with and eccentric rotor design?

A: The eccentric type is much more suitable for the complicated material situation, The eccentric rotor design reduces long-term wear due to heated ferrous build up, and can effectively avoid the device damage caused by impurity ferrous metal.

Exclusive the ferrous influence, the concentric type has a little bit better separation effect but must make sure no ferrous exist.

For any inquire about various metal solutions, please feel free to contact with us

EJET Eddy current separators, or non-ferrous separators, separate non-magnetic (non-ferrous) metals. They purify large bulk streams and/or separate non-ferrous metals for reuse. Eddy current separators have many uses. They can handle high capacities, because the conveyor belt separates and carries away non-ferrous metals continuously and fully automatically. An important factor for good separation is an even flow of material, supplied by a vibrating feeder or conveyor belt for example.

EJET separators are robustly built so they can remain operational day and night in even the most demanding applications, such as incinerator slag reprocessing. Application examples include:

1.Removal of aluminium caps for the glass recycling industry;

2.Removal of non-ferrous metals from slag from waste incineration plants;

3.Processing of scrap, electronics waste or household waste;

4.Elimination of impurities from recycled plastic streams for protection of injection moulding machines;

5.Recovery of casting residues in the metal casting industry.

And processing shredded scrap, demolition waste, packaging waste, aluminium salt slags, wood chips, glass or moulding sand.

Our machine has been exported over 60 countries and Acquired unanimous praise from international friends

Our Service

1. We cooperate with superior suppliers.

2. The test of materials is free.

3. Strict quality checks for every machine before packing.

4. Engineers available to service machinery overseas.

5. Sales service support, also technology support.

Prev: Scrap Motor Stator Copper Recycling Machine Hydraulic Power Waste Motor Cutting Machine

Next: High Gradient Aluminium Recycling Eddy Current Separator Aluminum Recycling

Our Contact